3DX System

How it Works

The Core and Die are components of the extrusion head that have been used since the 1970s in blow molding machines to vary the thickness of the plastic material, however, the profile of the extruded material can only be changed longitudinally. In our 3DX system, the ring is made from a special alloy that is deformed during extrusion by one, two or more electric, or hydraulic actuators, as required.

Advantages of the deformable ring system

Plastic material savings – Material is removed from unnecessary areas, so the weight of some parts of the product is reduced by more than 10%.

Lower cycle times – Thick sections take much longer to cool, so removing them allows you to open the mold sooner and have faster cycles.

Tighter specifications – Setting the molding weight to achieve minimum wall thickness at specific locations risks wasting material elsewhere.

Reduced distortion – Thick sections shrink more than adjacent thin sections causing distortion and “paneling.” Our 3DX offers the control needed to avoid this problem.

Increased resistance – Excessive wall thickness is one of the most common causes of drop test failure, as thinner sections have the ability to absorb energy, like the crumple zones of a car.

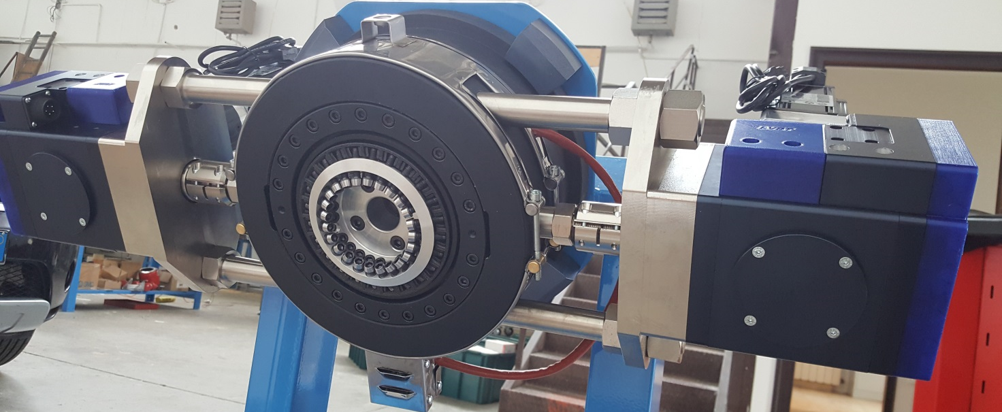

S1/3DX One Drive

The 3DX One Drive is the perfect solution for packaging containers.

The flexible ring is deformed equally on both sides by a single actuator located at the rear. In addition, the narrow and compact shape allows installation even in multi-cavity extrusion heads and, due to the low cost, a shorter payback time than the S2/3DX.

Using the S1/3DX System together with our SDC ensures the highest performance in thickness control.

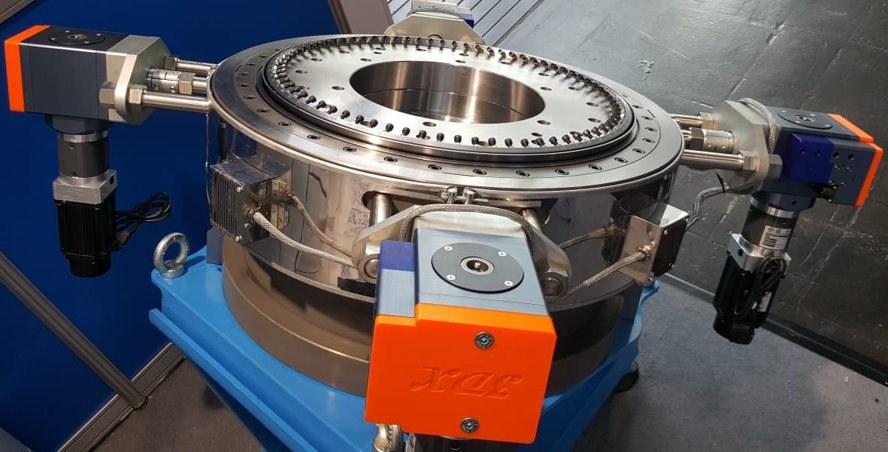

S2/3DX

The S2/3DX is the standard solution for technical parts and packaging of 20 liters and above.

The flexible ring is deformed dynamically by two actuators, placed opposite each other. The programmer profile typically has the same shape, but different profiles can be designed in case of more complex shapes.

Using the S2/3DX System together with our SDC or S2DC deformable core ensures maximum thickness control.

S4/3DX

The S4/3DX is typically used for large containers such as IBCs.

The flexible ring is deformed dynamically by four actuators placed at 90° to each other. The programmer profile typically has the same shape, but different profiles can be designed if more complex shapes are needed.

Using the S4/3DX System in conjunction with our SDC or S2DC deformable core ensures maximum performance in thickness control.

SDC

The SDC (Statically Deformable Core) is ideal for canisters and other non-round shapes. Complementary to our 3DX ring, this device allows you to shape the inner ring and optimize the profile, simply by adjusting a set of screws. The flexible section is made of the same special material we use on the 3DX ring, so the shape always returns to its original condition if the adjusting screws are loosened. The SDC is also available as a replacement part without the dynamically deformable 3DX system.

S2DC

The S2DC is very useful for complex shapes, such as automobile parts, and allows more precise adjustment of the final thickness.

Unlike the SDC, which has only one row of screws and pushes the inner flexible ring against the die, reducing the space, this device has 2 rows of screws and can also pull the ring, increasing the space between core and die. The S2DC is also available as a replacement part without the dynamically deformable 3DX system.

Share