Modernization to bring blow moulding machines back to life

Retrofit to revive blow molding machines

S.B.E. retrofit for hollow body blow molding machines

In the specific case of plastic blow molding packaging manufacturing, “retrofit” is a term that refers to upgrading existing plants to improve their performance and efficiency or to change their configuration according to production.

This can include upgrading the electronics, automation or mechanics of the plant. Retrofit has been used for many years to keep blow molding packaging plants up to date with market needs and the latest available technologies.

The benefits of our retrofit service for entrepreneurs and companies producing plastic blow molding packaging are:

- Increased efficiency: newer, more advanced machines can produce plastic packaging with greater speed and accuracy, thus increasing production capacity and reducing downtime.

- Reduced costs: new equipment is often more efficient and requires less maintenance than older equipment, reducing operating costs.

- Increased quality: new technologies enable higher quality, stronger and improved-looking packaging, resulting in customer satisfaction.

- Adaptability to customer needs: new functions and technologies can be added to existing machines to meet specific customer needs, increasing the flexibility of the production process.

- Compatibility with environmental standards: new machines can be designed to comply with the latest environmental standards, enabling companies to adhere to government regulations.

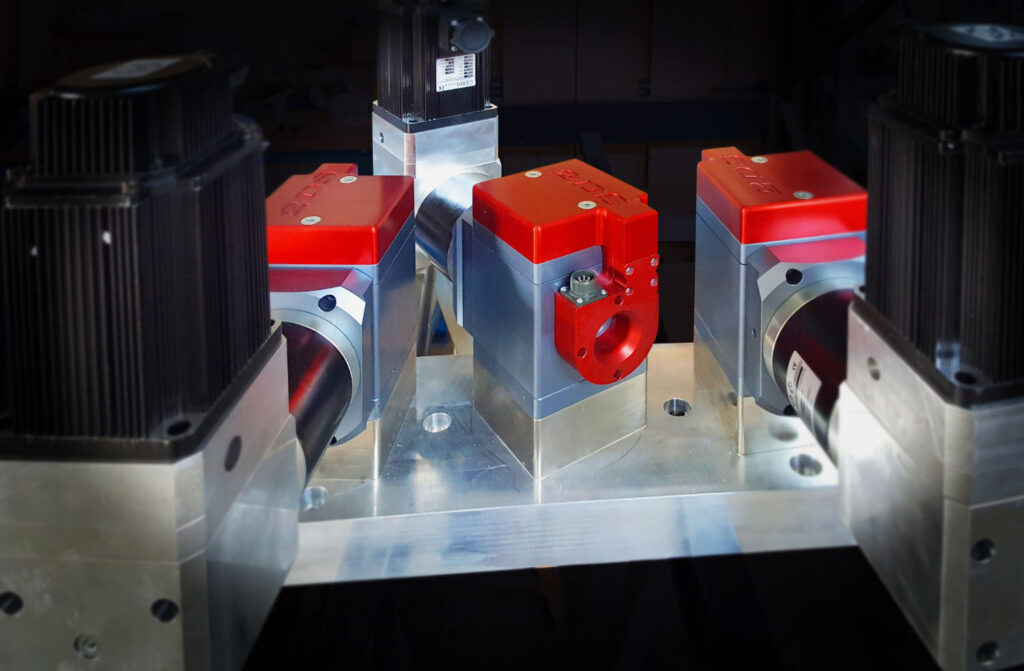

2DS Electric actuator

2DS dynamic dosing systems are part of the new generation of actuators designed for Parison thickness control with servo motors. We offer them in a range from 20 kN to 120 kN for any extrusion head model. They can replace the hydraulic servo piston without any modification to the machine’s PLC.

Blow moulding extrusion heads

We design and manufacture single-layer and CoEx extrusion heads on request. Our top-feed and Torpedo extrusion heads enable optimum Parison distribution and fast color change.

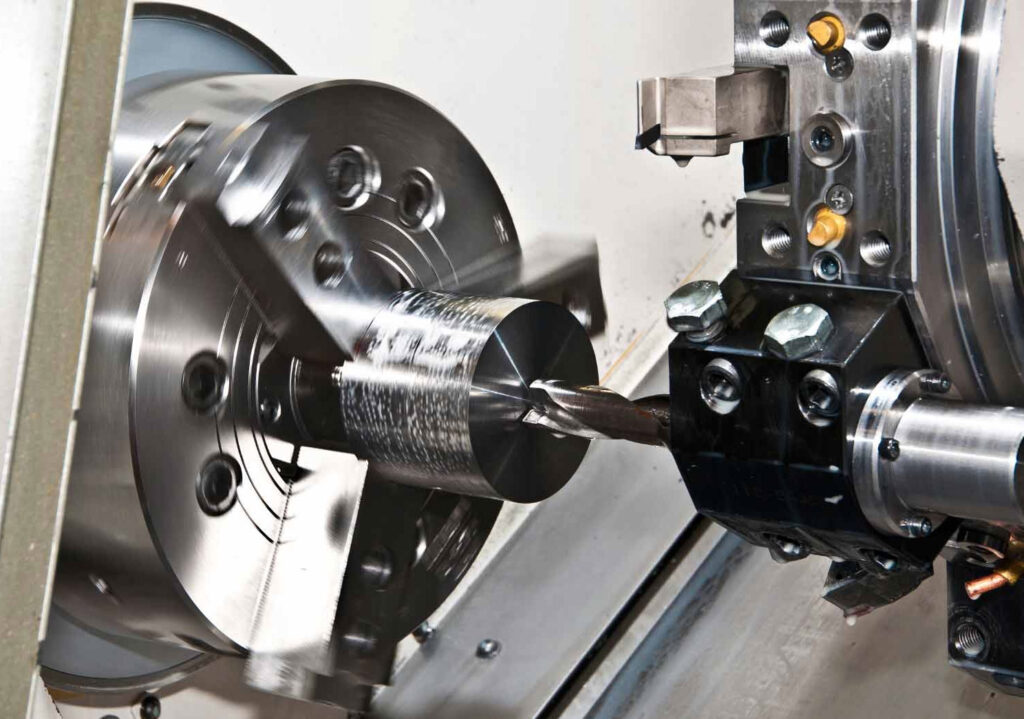

Extruders for hollow body blow molding

In cooperation with our partners, we manufacture screws, cylinders, mixers, screen changers or even entire extruder assemblies. If required, also with dedicated profiles and wear-resistant surface treatments.

S.B.E. supplies original spare parts, if necessary customized to customers’ needs.

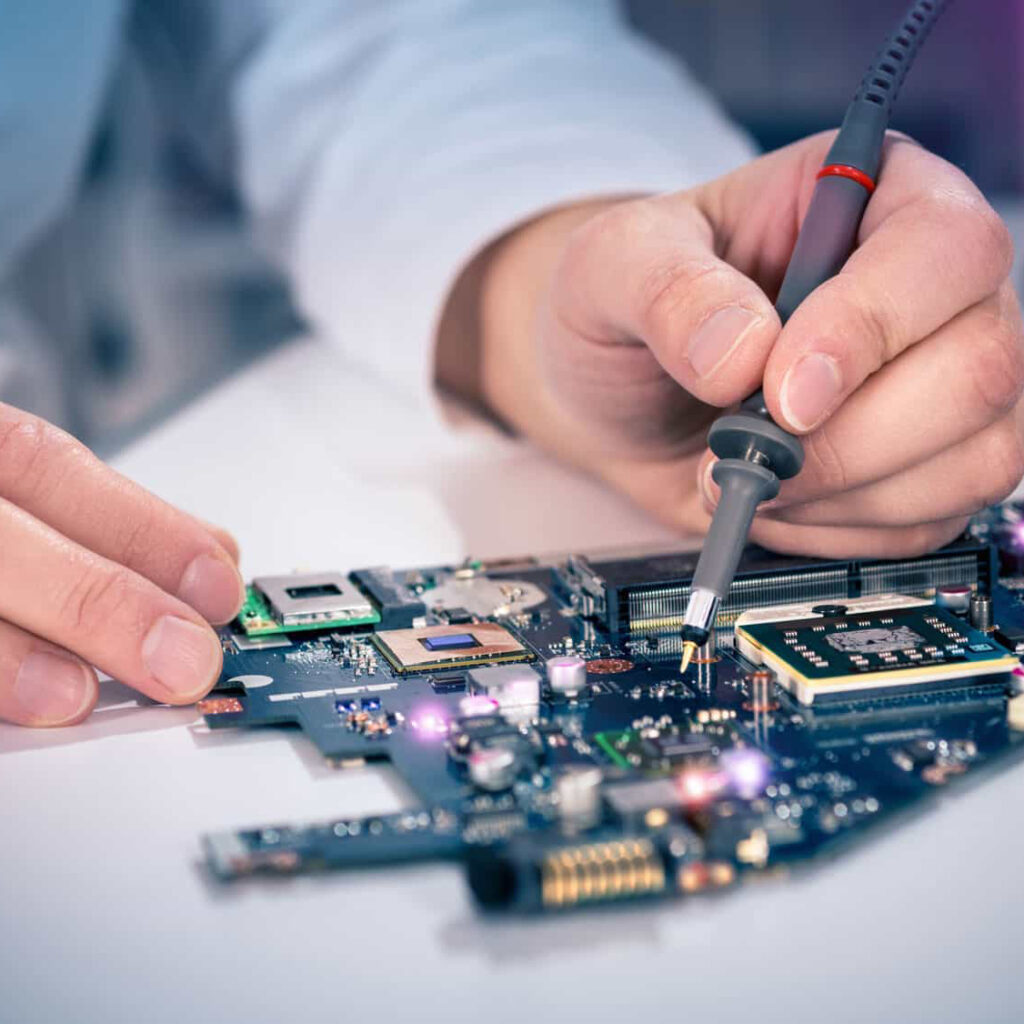

PLC electronics retrofit

Over the years, the aging of electronics installed on blow molding machines makes it increasingly difficult to find replacement parts.

Therefore, we offer PLC retrofit on two different platforms, depending on the type of blow molding machine and production needs. All systems use intuitive touch screen interfaces that allow complete control of machine functions. All PLC platforms support integration with WDM 4.0 for INDUSTRIE 4.0 data management.

We also propose the best solution to renovate the extrusion blow molding machine with both continuous extrusion technology and accumulator head, increasing its performance and commercial value.

Share